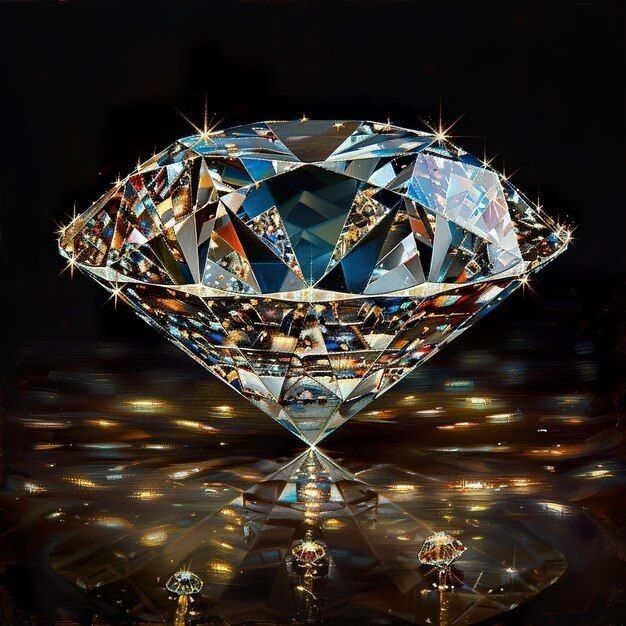

Diamonds have long been symbols of luxury, wealth, and timeless beauty. While all diamonds require precision and expertise in their transformation from rough stones to polished gems, the process of manufacturing large rough diamonds presents a unique challenge. At Eternity Gems, we specialize in sourcing, manufacturing, and facilitating trades for large rough and polished diamonds—a craft that demands the perfect blend of technology, artistry, and experience.

In this detailed blog, we take you behind the scenes of large diamond manufacturing, exploring the science, challenges, and expertise required to bring these rare and valuable gems to life.

The Uniqueness of Large Rough Diamonds

Unlike smaller diamonds, large rough diamonds require a completely different approach in their evaluation, cutting, and polishing processes. Their sheer size and potential value mean that even the slightest miscalculation can lead to millions of dollars in lost value.

Why Large Diamonds Are Special:

- Rarity and Value: Large rough diamonds (above 5 carats) are significantly rarer than their smaller counterparts, making them highly valuable.

- Unique Internal Structures: Unlike smaller diamonds, large stones often have more internal inclusions or structural complexities, which must be carefully analyzed before cutting.

- Higher Stakes in Cutting: A single mistake in cutting a large rough diamond can result in a huge loss in carat weight, reducing the final value significantly.

- Global Demand: Large diamonds are highly sought after in luxury jewelry, investment portfolios, and collectors’ markets, making precision in manufacturing even more critical.

At Eternity Gems, we specialize in handling these unique, high-value diamonds, ensuring that every stone reaches its maximum potential in brilliance, clarity, and weight.

The Process of Manufacturing Large Rough Diamonds

Large diamond manufacturing is both an art and a science, requiring expertise at every stage. Here’s how Eternity Gems ensures that each diamond is crafted to perfection:

1. Sourcing and Procuring Large Rough Diamonds

The journey begins with sourcing rough diamonds from ethical and conflict-free mines across the world. At Eternity Gems, we prioritize responsible sourcing, working with certified suppliers who adhere to Kimberley Process regulations to prevent the trade of conflict diamonds.

Before a diamond reaches our cutting experts, it undergoes:

- Initial Evaluation: Experts examine the rough diamond for size, shape, clarity, and potential yield.

- Fluorescence and Inclusion Check: Large diamonds often have natural inclusions. Advanced imaging techniques help us determine the best cutting plan.

- Strategic Planning: Deciding how to cut a large rough diamond requires weeks of analysis to ensure maximum carat retention and avoid unnecessary weight loss.

2. Advanced Technology in Diamond Cutting

The cutting of large diamonds requires a mix of technology and human expertise. Eternity Gems utilizes state-of-the-art diamond cutting equipment to ensure precision and brilliance.

Key Technologies Used in Cutting Large Diamonds:

- 3D Mapping and Scanning – Advanced laser scanning helps create a digital blueprint of the diamond, allowing cutters to plan the most efficient cut.

- Laser Cutting & Cleaving – Instead of traditional cleaving methods, we use high-precision laser technology to separate sections of the rough diamond with minimal risk.

- Bruting (Shaping the Diamond) – This is the process of giving the diamond its basic round shape before the faceting begins.

- Polishing and Faceting – Using cutting-edge robotic polishing machines and expert diamond cutters, we craft precise facets that enhance the diamond’s light reflection and overall brilliance.

At Eternity Gems, our focus is on minimizing waste while maximizing beauty, ensuring that each large rough diamond is cut into the most profitable and stunning polished gem possible.

3. The Role of Master Craftsmen in Large Diamond Manufacturing

While technology plays a crucial role, human expertise is irreplaceable in diamond cutting. Our master diamond cutters at Eternity Gems have years of experience handling large stones and making critical decisions on every cut.

Key Considerations for Large Diamond Cutting:

- Best Shape Selection – Should the diamond be cut into a round brilliant, an emerald cut, or a unique fancy shape?

- Avoiding Carat Loss – Cutting a diamond too aggressively can result in a significant weight drop, reducing value.

- Maximizing Brilliance – The goal is to create the most brilliant stone possible without sacrificing too much carat weight.

By combining experience with precision technology, we ensure that each diamond is flawlessly crafted to meet the highest standards of luxury and refinement.

Facilitating Trades for Polished Large Diamonds

Once a large rough diamond has been expertly manufactured into a polished masterpiece, Eternity Gems plays a key role in facilitating its trade to global buyers, luxury jewelry brands, and investors.

1. Market Insights & Pricing Strategies

- Large diamonds require careful pricing based on clarity, color, cut, and market demand.

- We leverage market trends and valuation reports to ensure our clients receive the best returns on their investments.

2. Certification & Transparency

- Every large diamond is certified by leading gemological laboratories such as GIA, IGI, or HRD.

- We ensure complete transparency in the sourcing and valuation process, providing clients with full provenance details.

3. Global Reach & Trade Networks

- With a strong international network, we connect sellers and buyers across luxury markets in the USA, Europe, the Middle East, and Asia.

- Our expertise in high-value diamond transactions ensures seamless, secure, and profitable trades for all parties involved.